Call: 08045479524

Anti Corrosion Coating Services

Price 99 INR/ Square Foot

MOQ : 100 Square Foots

Anti Corrosion Coating Services Specification

- Finishing

- Smooth, Glossy, Matt Available

- Service Duration

- 1-7 Days Depending on Project Size

- Adhesion Strength

- High Bonding to Substrates

- Payment Mode

- Online, Offline

- Environmental Compliance

- Low VOC, Eco-Friendly Options

- Maintenance

- Low Maintenance Required

- Packing Type (for materials)

- Drums, Buckets

- Shelf Life of Coating Material

- 12-24 Months

- Temperature Resistance

- Up to 200C

- Preparation Required

- Surface Cleaning, Sand Blasting Possible

- Coating Material

- Epoxy, Polyurethane, Zinc-Rich Primers

Anti Corrosion Coating Services Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 5000 Square Foots Per Month

- Delivery Time

- 7-10 Days

About Anti Corrosion Coating Services

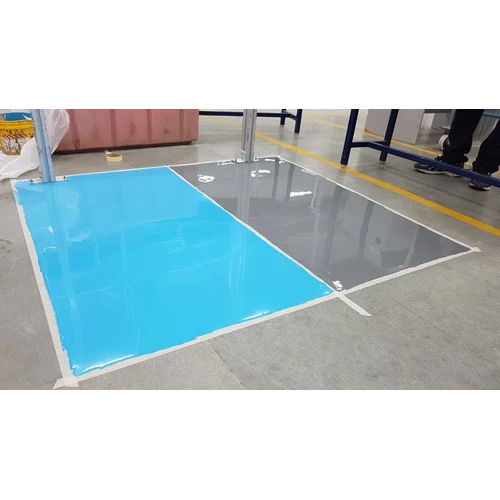

Anti Corrosion Coating Services provide protection for metal surfaces against corrosion caused by environmental factors such as moisture, salt, chemicals, and other corrosive agents. This Improves safety by preventing structural failures and protecting workers from exposure to corrosive materials. They are known for their excellent adhesion and durability, epoxy coatings provide strong protection against corrosion, abrasion, and chemicals. These coatings offer high chemical resistance and are often used as a topcoat to provide UV protection and enhance durability. Anti Corrosion Coating Services offer high heat resistance and are commonly used in high-temperature applications.

Advanced Protection for Multiple Applications

Our coatings are engineered to protect steel and other substrates from corrosion, enhancing longevity in harsh environments. Whether you need epoxy for high durability or zinc-rich primers for barrier protection, our service adapts to your requirements. Each project receives comprehensive surface preparation, including cleaning and sand blasting, ensuring optimal coating adhesion and performance.

Customizable Finishes and Reliable Durability

Clients can specify their preferred finishsmooth, glossy, or mattwhile still benefiting from high bonding strength and resistance to temperatures up to 200C. Our eco-friendly, low VOC materials are supplied in convenient drums or buckets, with a shelf life of 12-24 months. This guarantees both flexibility and sustainability, making our solutions ideal for diverse industry needs.

FAQs of Anti Corrosion Coating Services:

Q: How is the anti corrosion coating applied to surfaces?

A: The coating application involves thorough surface cleaning, followed by optional sand blasting for better adhesion. Materials like epoxy or zinc-rich primers are then applied by our skilled technicians, ensuring a smooth and effective coating layer.Q: What types of anti corrosion coatings are available with your services?

A: We offer epoxy, polyurethane, and zinc-rich primers, each selected based on the environment and substrate. These materials provide excellent protection against corrosion and are suitable for various finishesincluding smooth, glossy, or matt.Q: When should I consider anti corrosion coating for my assets?

A: Anti corrosion coating should be considered when your metal surfaces are exposed to moisture, chemicals, or varying temperatures. Application is recommended before visible signs of corrosion and can be scheduled for completion within 17 days, depending on project size.Q: Where are your anti corrosion coating services available in India?

A: We provide services nationwide in India and also export coating materials globally. As a manufacturer, supplier, and service provider, our reach includes industrial, commercial, and infrastructure projects across the country.Q: What is the process for booking and payment of coating services?

A: Clients can book services online or offline. The payment methods are flexible, ensuring convenience. Our team will guide you through material selection, preparation, and application, streamlining the process for timely project completion.Q: What are the benefits of choosing your eco-friendly, low VOC coatings?

A: Our coatings are designed to minimize environmental impact while delivering robust protection. Low VOC formulas ensure safer application and compliance with environmental standards, supporting sustainability in your projects.Q: How long do the anti corrosion coatings last, and what maintenance is required?

A: With a shelf life of 1224 months for coating materials and minimal required upkeep, our coatings continue to provide long-term durability for your surfaces. Routine inspections are recommended, but overall maintenance demands remain low.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Coating Services Category

Industrial Epoxy Coating Services

Price 120 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry